Crusher Parts Manufacturers-Qiming Casting

Crusher parts manufacturers, Qiming Casting Foundry, specialists in replacement parts for the mining and aggregate industries, mainly manganese casting parts and chrome casting parts, which included ball mill liners, jaw plates, cone liner , bowl liners and so on. it means supplier of a full line of extended-wear manganese castings for all types and from all manufacturers of crushers.

Qiming Casting Advantages:

-

- High manganese steel crusher hammers are cast using clean manganese steel melt, which performs well even under the most severe working conditions.

- Our unique melting process offers clean manganese steel, in some cases, our hammers offer up to 50% longer service life.

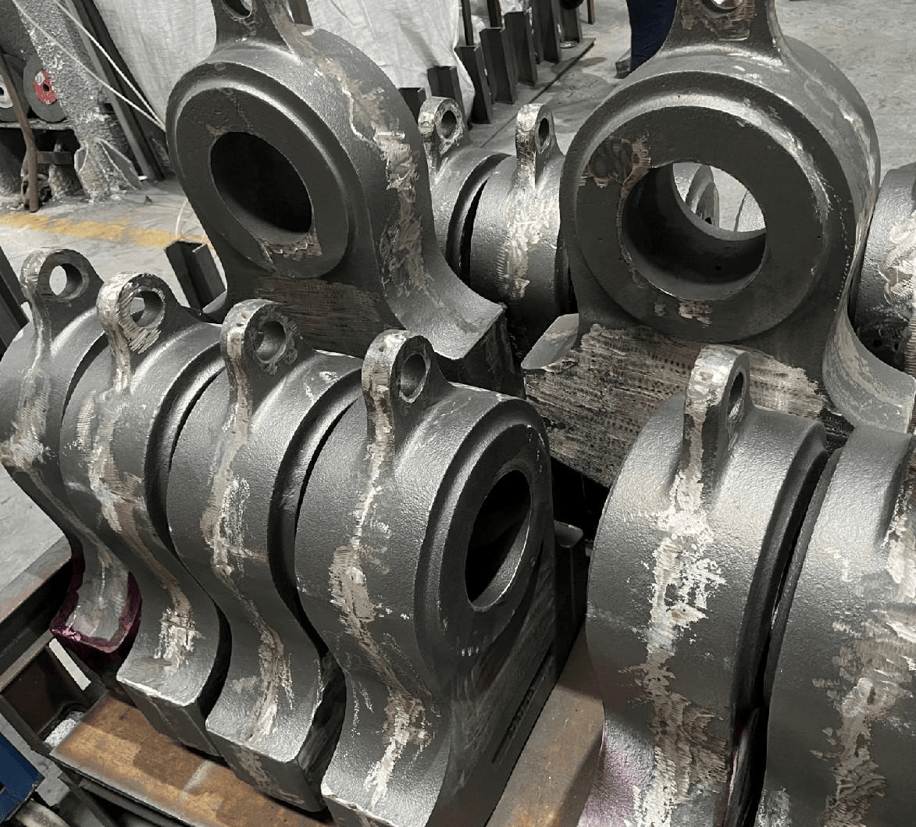

- Overall lower operation cost, Qiming Casting offers a wide range of OEM parts, aftermarket/replacement parts can be made to meet your specific requirements,supplies replacement all types Crusher Parts for all major models of crusher.

Crusher liner productive process:

1. Our sale team got the necessary detail information from customers:

(1)Quantity.

(2)Material Choice. For different types crusher parts,choose different material. For example, blow bars material often choose high chrome, however, cone crusher parts choose high manganese.

(3)Drawings.Customer send us drawings or we supply drawings to check.

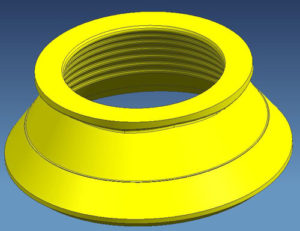

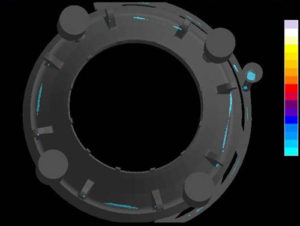

(4) Make 3D model and performs simulations to determine best quality control method.

(5)Make Model (LFC, wood models or steel models )and sandmaking.

(6)Casting and cooling time, gating and risers (feeders) are ready to be removed.

(7)heat treatment and water quenching.

(8)Machining and surface finishing.

(9)printing,package and send.

Crusher Parts Manufacturers---Qiming Casting

Manganese steel history can be up to 200 years ago, user, researchers, and producers have never stopped trying different ways to increase the mechanical properties, working life, and wearable of manganese steel. Changing the composition by adding elements such as Mn Mo, C, Si, and some others, this method has been proven very useful but in other cases, results are not conclusive. We now have 14% manganese, 18% manganese, and 21% manganese liners for different working conditions, As we know, producers are now offering 25% manganese steel.

Qiming Casting has been producing manganese steel liners for 20 years and tried quite a few different approaches trying to improve product quality. who has always focused on producing the "best" manganese steel and high-quality after-sale service.