Crusher Hammer Characteristics And Classification

Crusher Hammer is one of the main crusher wear parts in the hammer crusher, which install on the hammer crusher rotor. When the hammer crusher is running, the crusher hammer direct hits the raw material. Hammers play an important role in crushing different types of materials, so there are kinds of material crusher hammer classifications.

Crusher Hammer Performance Characteristics

- The impact on the material has increased. Because the hammer's center of gravity is in the radial radius of radial shift, the hammer in the middle of the line speed increases. Hammer crusher hammer impact on the material work has increased, thus improving the crushing effect.

- The effective wear of the crusher hammers has increased.

- Reduce the grain size and improve the yield.

- Improve the grinding result.

Crusher Hammer Classification

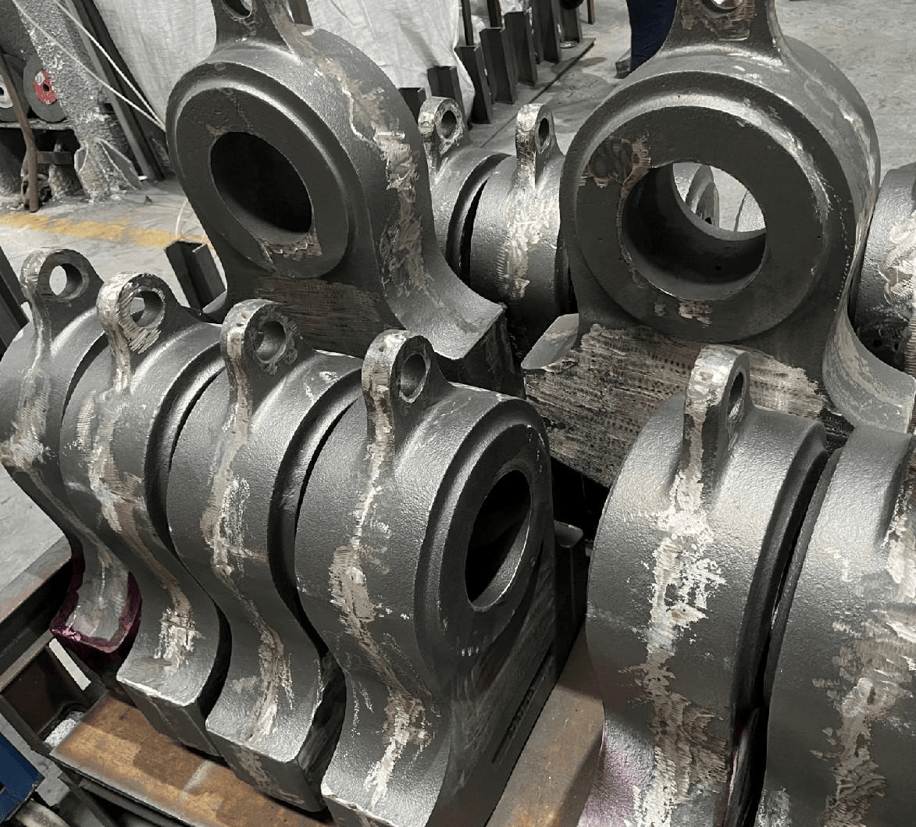

Forging Hammer

Forging hammers are mainly used in crushing pebbles, coal gangue, and limestone. Forging Crusher hammer with high-quality train wheel steel (65Mn material, good impact resistance, toughness, wear resistance, and not easy to break) the use of forging machinery repeatedly forging metal billet to produce deformation in order to obtain a certain mechanical property, A certain shape, and size, after a special quenching heat treatment methods to ensure that the work area of the hammer to be high hardness, high wear-resistant properties. Through forging can eliminate the metal in the smelting process, such as casting defects such as loose, optimize the microstructure, and because of the preservation of a complete metal flow line, forging mechanical properties are generally better than casting.

Manganese Hammer

High manganese steel wear-resistant hammer, reliable quality, wear resistance three times more than traditional material crusher hammer. The crusher hammer is widely used in the new dry cement production line supporting large limestone crusher. High manganese steel crusher hammers have good toughness, good technology, and low price. its main feature is the greater impact or contact stress under the action of the surface layer will quickly produce work hardening, the work hardening index is higher than other materials by 5 -7 times, and the wear resistance can be greatly improved.

Chrome Hammer

High chrome hammer hardness is excellent, are high-quality wear-resistant materials in the crusher support hammer and impact crusher that has been widely used, but the high-chromium alloy toughness is poor, and easy to break in the absence of a support hammer shell. High-chromium composite hammer, hammer handle with high manganese steel, hammerhead work area with high-chromium alloy, the two together, so that the hammer has a high hardness, hammer handle with high toughness, give full play to the two materials, to overcome their own advantages A single material shortcomings, to meet the performance requirements of the hammer. Particularly suitable for crushing high-hardness materials, such as quartz stone, basalt, and so on.

Carbide Alloy Hammer

Carbide Alloy Hammer compared to other material products, has higher hardness, bending strength and impact, better hardness, and lower cost. It solves the high-manganese material prone to crack, desoldering, collapsing mouth, out-of-blocks, and other problems.

Dual Hardness Alloy Steel Hammer

Qiming Casting has developed a new hammer series, Dual Hardness Alloy Steel Hammer, with the goal of extending the lifetime of these tools. Featuring a special alloy, the high-quality cast-steel hammers from the Qiming Casting ensure substantially enhanced economic efficiency and can be used in all types of shredder series.

The special alloy is harder on key areas and helps to keep the original shape of the hammer for longer. With the correct hammer profile for your rotor, the shredder will feed better since it grabs the material and pulls it in, resulting in a higher production rate over a longer period of the life of the hammer (it keeps the sweet spot longer). This alloy has a higher yield point than manganese (it deforms less); consequently, you can push its geometry and use a thicker hammer that will not jam in your rotor. This gives you a more powerful striking force and improves material breakage and non-ferrous recovery.